As the global construction industry moves toward greater efficiency, sustainability, and industrialization, Modular Integrated Wall Panels have become a key solution in modern building systems. With fast installation, superior energy performance, and stable quality, this innovative system is reshaping how buildings are designed and built worldwide.

1. What Is a Modular Integrated Wall Panel?

A Modular Integrated Wall Panel (MIWP) is a composite wall system that combines the structural layer, insulation layer, and finishing layer into one prefabricated module. These panels are manufactured in a controlled factory environment and quickly assembled on-site, eliminating the need for bricklaying, plastering, or insulation work.

A standard FASEC modular wall panel includes:

-

Structural Layer: Light or galvanized steel frame providing superior strength and dimensional stability.

-

Insulation Layer: High-performance materials such as EPS, PU, PIR, or rock wool, ensuring excellent energy efficiency.

-

Finishing Layer: Options include metal panels, cement boards, aluminum composite panels, or stone-look finishes.

-

Connection System: Modular splicing design for fast installation and convenient future maintenance.

This fully integrated design not only boosts construction efficiency but also enhances building aesthetics, sound insulation, fire resistance, and moisture protection — making it an essential part of modern prefabricated buildings.

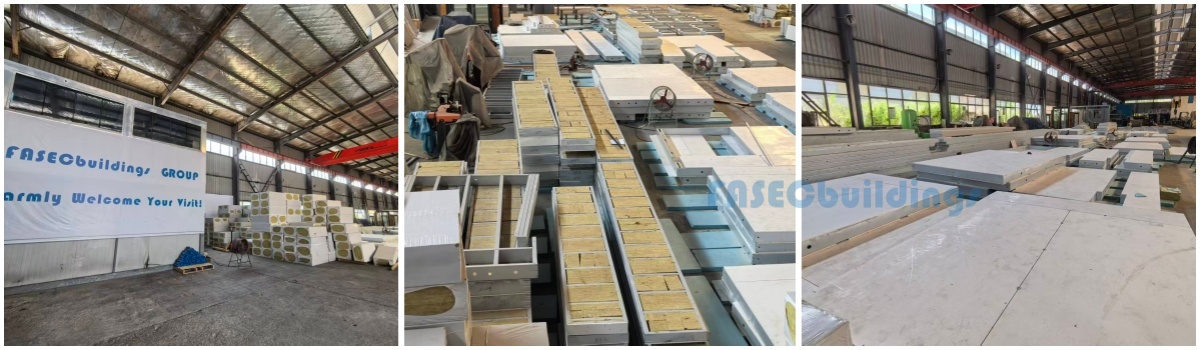

2. FASECbuildings Group’s Manufacturing Advantage

FASECbuildings Group (FASEC) is one of China’s leading manufacturers of modular and steel structure systems. With years of experience in international construction projects, FASEC has established a strong reputation for delivering high-performance wall panels and modular building systems that meet ISO 9001, EN1090, and AWS D1.1 standards.

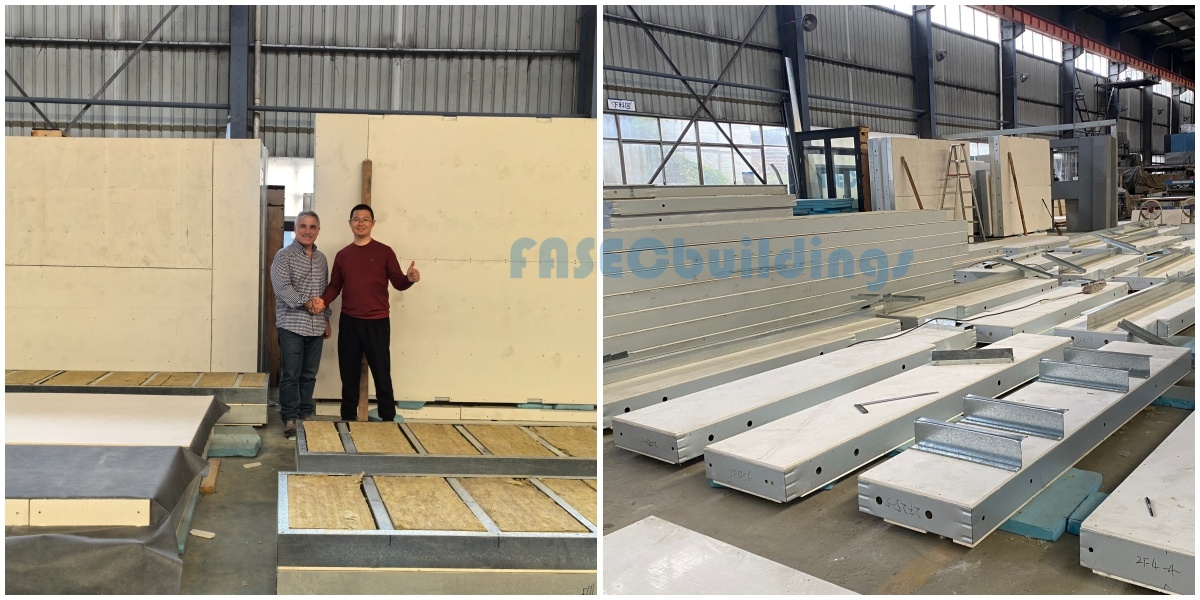

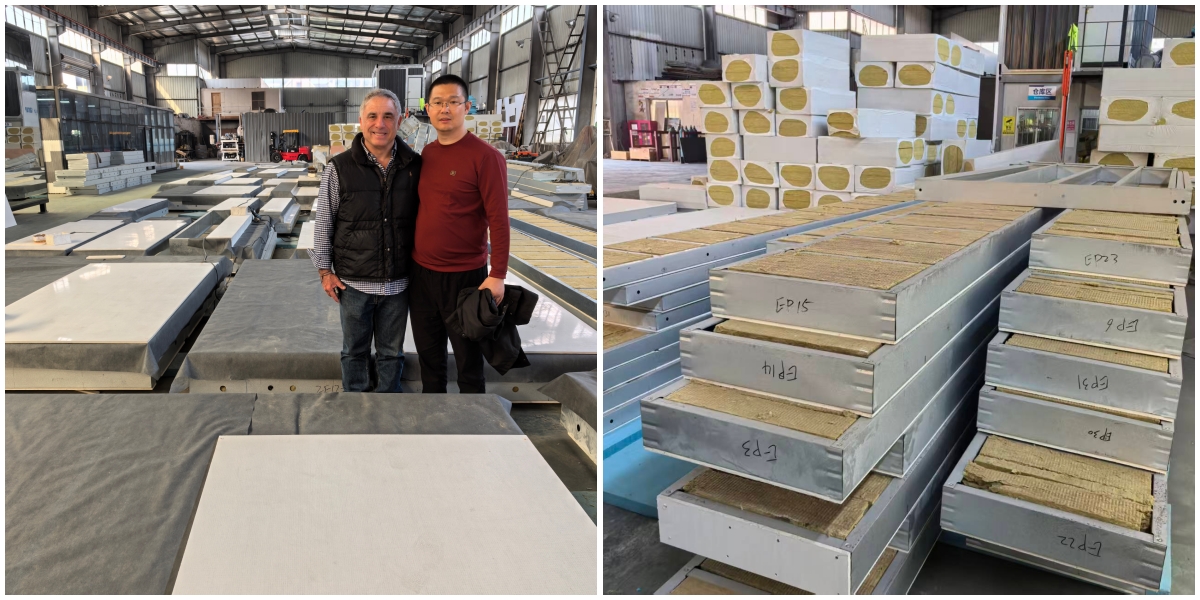

Inside FASEC’s production facility, each wall panel undergoes strict quality control — from precision cutting to surface finishing — ensuring accuracy and consistency in every batch. The company integrates modern CNC equipment, automated forming lines, and a dedicated testing lab to guarantee product reliability.

Recently, several overseas clients from Australia, the UAE, and Southeast Asia visited FASEC’s factory to evaluate our Modular Integrated Wall Panels in person. During their visit, they observed the full production process — from raw material handling to assembly testing — and were impressed by our product quality, modern equipment, and efficient management system.

Such visits not only enhance customer confidence but also allow FASEC to understand specific regional requirements and offer customized wall systems for various climate and building standards.

3. Key Product Advantages

FASEC’s modular integrated wall panels offer a balance of industrial precision and architectural flexibility, providing:

-

High Structural Strength: Made with high-grade galvanized steel or aluminum frames, ensuring resistance to wind, load, and seismic forces.

-

Energy Efficiency and Thermal Comfort: Filled with dense insulation cores to maintain stable indoor temperatures and reduce energy consumption.

-

Aesthetic Versatility: A variety of finishes and colors for residential, commercial, or industrial projects.

-

Quick Installation: Modular connection design allows for clean, fast, and low-noise on-site assembly.

-

Full Customization: Panel thickness, dimensions, and surface materials can be tailored to meet client specifications.

4. Broad Application Scenarios

FASEC modular wall systems are widely used in:

-

Residential: Villas, apartments, dormitories, worker housing;

-

Commercial: Retail centers, showrooms, logistics and storage buildings;

-

Public Projects: Schools, hospitals, disaster relief shelters, and temporary facilities;

-

Modular Buildings: Camps, site offices, containerized housing, and relocatable units.

In a recent Southeast Asian project, the use of FASEC modular wall panels resulted in a 40% reduction in construction time, while also improving insulation performance and appearance. In a Middle Eastern commercial development, FASEC systems enabled the client to maintain energy efficiency in extreme desert heat.

5. Sustainable and Smart Manufacturing

Sustainability is a core part of FASEC’s philosophy.

All wall panels are produced using recyclable steel and eco-friendly insulation materials. The factory process minimizes carbon emissions, waste, and noise pollution — fully aligned with global green building standards.

To ensure precision and transparency, BIM technology and digital modeling are integrated into every project. This enables seamless coordination between design, manufacturing, and on-site installation, ensuring that every detail is traceable and consistent.

6. Partnering with FASEC — Building Smarter, Faster, Greener

In the modern construction industry, where speed and reliability define competitiveness, FASECbuildings Group stands as a trusted global partner.

With its motto — High Standard, Fast Delivery, International Quality — FASEC continues to provide clients worldwide with turnkey modular building solutions, combining innovation, quality, and cost efficiency.

Whether for residential housing, industrial facilities, or modular complexes, FASEC meta cladding panels deliver proven performance and sustainable value — helping customers build faster, smarter, and greener.

FASECbuildings Group — Empowering global construction through modular innovation and sustainable engineering.

English

English