Unitized glass curtain wall systems are composed of large glass units that are created and glazed within a factory and then sent to the construction site. Once arriving on site, the units can then be hoisted onto anchors connected to the building whatever concrete or steel buildings. High quality, due to tight tolerances of fabrication in a climate-controlled environment, is only one hallmark of this type of system. Because there is no on-site glazing, another major benefit of using a unitized system is the quicker speed of installation. The system can be installed in a third of the time of a stick-built system which means a lot of site time saving. This system is well suited for cases where there is a large volume of prefabricated unitized panels required, where there are higher field labor costs (thereby shifting the labor to a more cost-effective factory work force), where higher performance is needed (for wind loads, air/moisture protection, seismic/blast performance), for taller structures, and more regular conditions for panel optimization.

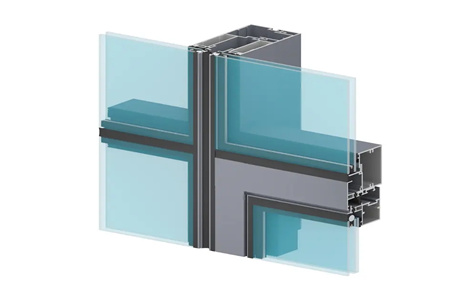

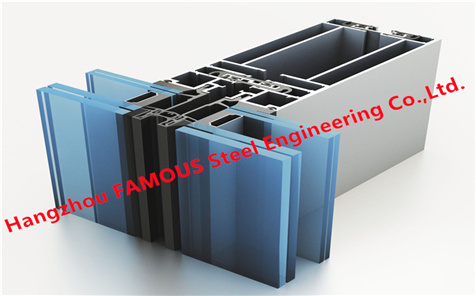

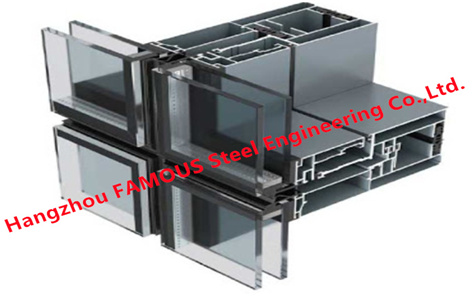

The unit glass curtain wall assembles panels and metal frames (beams, columns) into curtain wall units in the factory. The structural features of unit glass curtain walls in the form of curtain wall units are: first, the units (skeleton materials, glass, insulation Insulation materials) are assembled into a complete frame in a special factory, and then transported to the construction site. At the construction site, only one curtain wall unit needs to be installed and fixed to the main structure of the building in turn.

Because the columns are connected, their specifications should be consistent with the storey height and column spacing. When connected to a floor or beam, the height of the curtain wall should be equivalent to the story height or a multiple of the story height; when connected to the columns, the width of the curtain wall should be equivalent to the column spacing.

The advantages of unit glass curtain wall are: simple and fast installation on the construction site, shortening the construction period of the project.

Specification:

|

Material: |

specification: |

|

Length |

4m or as per customer’s requirement |

|

Width |

1.5m or as per customer’s requirement |

|

Height |

0.2m or as per customer’s requirement |

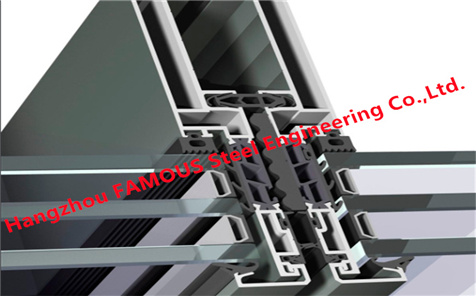

Only one unit-to-unit splice (usually a silicone sheet or patch) needs to be field-sealed, and only one anchor per mullion needs to be attached to the face or top of the floor slab. Interlocking unitized glass curtain wall frame members are weathered and can be sealed to one another, both horizontally and vertically. This accommodates thermal expansion and contraction, inter-story differential movement, concrete creep, column foreshortening, and/or seismic movement. Most unitized curtain wall systems are installed in a sequential manner around each floor level, moving from the bottom to the top of the building.

Application:

|

HOW TO CHOOSE FROM STICK and UNITIZED CURTAINWALL SYSTEMS |

||

|

Selection Criteria |

Stick Curtain wall |

Unitized Curtain wall |

|

Project Size |

Small |

Large |

|

Wall Configuration |

Complex |

Repetitive (Large expanses of flat wall) |

|

Joint Pattern |

Random |

Uniform horizontal sill line |

|

Glazing |

Field |

Factory |

|

Inter-story Movements |

Very limited |

Inter-locking frames accommodate movements |

|

Quality Control |

Subject to site variables (Both environment and equipment) |

Controlled factory conditions |

|

Modification |

Can be cut-to-fit in the field |

Pr-engineered |

|

Sealing |

Subject to site variables |

Minimal field sealing |

|

Field Labor Cost |

High (Many parts to track and assemble) |

Low |

|

Field Labor Duration |

Slow |

Fast (Often setting 75 sqft or more per unit) |

|

Access and Safety |

Exterior access required |

Set from the interior (Exterior optional) |

Although unitized, pre-glazed curtain wall system is particularly suited to high-rise building construction or projects with large quantities of module repetition or whenever 4-sided capless system is required; it is also used popularly on any size project that demands it.

Whether your project requires a standard or custom framing system, we are capable to design, fabricate and install the glass facade curtain wall as per your needs, by providing a quality product.

All our pre-glazed facade curtain wall systems are fabricated, assembled and glazed within the controlled environment of our manufacturing facility. This will bring greater quality control and the ability to pr-construct our frame modules before the building’s structure is erected; it’s also very helpful to accelerate the close-in of the building, since our installation team can work on sections of the building as they become available; while minimizing delays due to weather conditions.

Nowadays the unitized curtain wall system have become the preferred method for enclosing buildings, as more building owners, architects and contractors conclude the benefits of this type of construction. Unitized systems allow buildings to be enclosed quickly, which can help to speed up the construction process leading to earlier occupation. The fabrication process for unitized systems is more consistent than for stick-built curtain walls, as unitized wall systems are constructed in almost an assembly line fashion, indoors, and under controlled environmental conditions.

Related Products

- Address

No.3 Beishang New City, GongShu District, Hangzhou China

-

Phone

+86-18072735884

-

Landline

+86-571-88688170

English

English