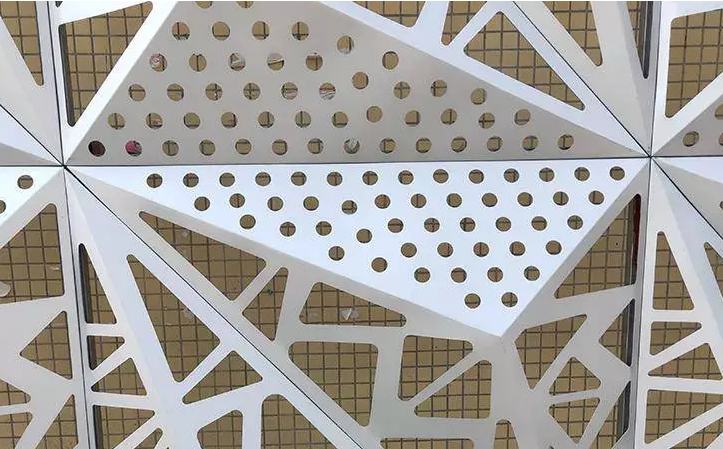

Decorative aluminum perforated panel

Also named decorative aluminum perforated plate or decorative aluminum perforated sheet, is a very popular ideal material for architecture cladding, ceiling and facade now.

Comparing with common metal plate material, decorative aluminum perforated panel is very light and strong strength, especially it has changing style, colorful surface spraying, and excellent rust resistance. So it is widely used in pavilions, airport terminals, high railway stations, supermarkets, sitting rooms, sports stores, hotels, villas, shopping malls, clubs within such as building exterior walls or ceilings.

Technical Information:

Material Grade: Aluminum alloy 6063 and etc.

Thickness: 1–6 mm

Hole Patterns: Regular decorative holes, free pattern holes, unrestricted art holes

Panel Size: width ≤ 2000 mm, length ≤ 4 000 mm

Process Support: Bending, welding

Holes Making Methods: Ordinary CNC punching, CNC turret punching, laser cutting

Surface Treatment: Powder coating, PVDF (Fluorocarbon) coating, Anodize oxidation

Variety of Decorative Holes

The hole patterns of decorative aluminum perforated panels can come in various forms. The most common are the regular decorative holes punched out by an ordinary punch press, which can form various simple geometric shapes such as circles, squares, triangles, etc. Another method is using CNC turret punching machines to punch out more complex and varied hole patterns in a free mode. This method allows for the flexible design of holes in different sizes and arrangements to meet various decorative design needs. Using laser cutting, it is possible to create more free and artistic hole patterns. Laser cutting has virtually no limitations and can cut out various complex shapes, achieving more personalized and diverse decorative effects.

Features of Decorative Aluminum Perforated Panel

1) A wide range of colors and openings, good decoration.

2) Openings permit free flow of light, heat, sound & air.

3) It won’t unravel when cut, unlike woven wire mesh.

4) Available in a variety of mesh configurations and decorative patterns.

5) Cost effective and environmentally friendly.

6) Light weight, fine rigidity, high strength.

7) Durability and low maintenance.

8) Good weather and corrosion resistance.

Applications

Decorative aluminum perforated panel has countless applications in architectural, commercial, industrial, building and other industries, ideal decorative applications include:

Architecture and interior design: It is used for decorating building facades, interior partitions, ceilings, staircase railings, etc., adding beauty and design to buildings.

Indoor furniture: It can be used for making furniture surfaces, screens, home decor items, etc., adding unique decorative effects to the home environment.

Artistic decoration: In the fields of art creation, sculpture, and carving, it can be used to create various decorative artworks.

Commercial display and billboards: It is used for decoration in commercial spaces and the production of billboards, increasing visual appeal and promotional effects.

Automotive and transportation: It is used for car interiors, motorcycle shells, etc., adding personalized designs to vehicles.

- Address

No.3 Beishang New City, GongShu District, Hangzhou China

-

Phone

+86-18072735884

-

Landline

+86-571-88688170

English

English