Perforated metal is used for many applications because of its durability, malleability and easy installation and maintenance. Sheet metal improves architectural designs by providing expanded design and functional elements to a building. Plus, it’s recyclable and can help you reduce energy bills, making it an economical choice.

Perforated metal involves sheet material that has been stamped, punched, or crafted to form a series of holes, slots, or ornamental shapes. This manufacturing technique can utilize several types of metals, including steel, aluminum, stainless steel, copper, and titanium. Beyond boosting the structural appearance of metal, perforating offers practical advantages like enhanced protection and noise mitigation.

1. Environmentally Friendly

Customers care about sustainability, and perforated metal is one of the most environmentally friendly building materials available. Before it even arrives at its destination, sheet metal is lighter than other materials, reducing transportation fuel use. Green choices like using perforated metal can positively reflect on your brand and attract new business.

A lot of sheet metal is made from recycled material and is long-lasting. Scrap metal from the perforations can also be gathered, recycled, and formed into new sheets. The perforations result in less metal used overall, maximizing your resources. You’ll also be able to re-claim a piece of metal after its functional architectural lifestyle ends.

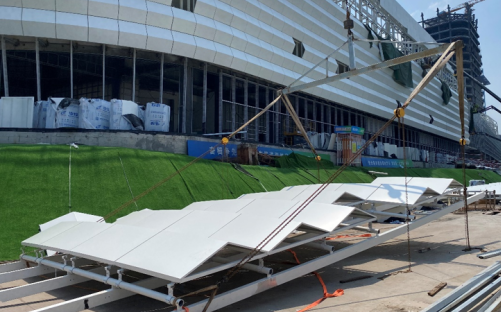

Additionally, perforated metal sunscreens and sunshades are energy-efficient. They deflect light, heat, and radiation from the sun while still allowing for ventilation. Buildings experience a more consistent internal temperature while still letting natural light filter inside — all with less energy use to save on utility costs.

With a variety of patterns to choose from, you have some control over the level of sunlight that enters a building. For example, 1/8-inch holes don’t permit much light to come through. A building will also have the appearance of a solid wall if the holes are smaller and closer together. It’s important to select the correct thickness in addition to proper hole sizes and spacing.

Sunshades can also increase your building’s aesthetic appeal with custom designs, multiple colors, and even the ability to implement images and logos into the design.

2. Aesthetics

All architectural designers strive to create aesthetic, durable, and functional projects. Perforated metal facade systems are durable and highly customizable, making them a modern, aesthetic and practical solution. The nature of sheet metal allows you to bend it to your desired design easily. With different hole shapes and sizes, thicknesses and finishes, you’ll be able to get the custom design you want.

Additionally, you can implement graphics, photographs, logos, or text into your perforated metal panel design to give panels a unique flare. Perforated metal signage is a popular application for perforated metal imaging.

Architects also use sheet metal for a variety of other design functions, including:

Perforated facade architecture: Because perforated metal is easy to work with and comes in a range of colors and finishes, it’s an excellent choice to give your building a unique flair. For example, you can use unique hole patterns to create eye-catching patterns, like branches.

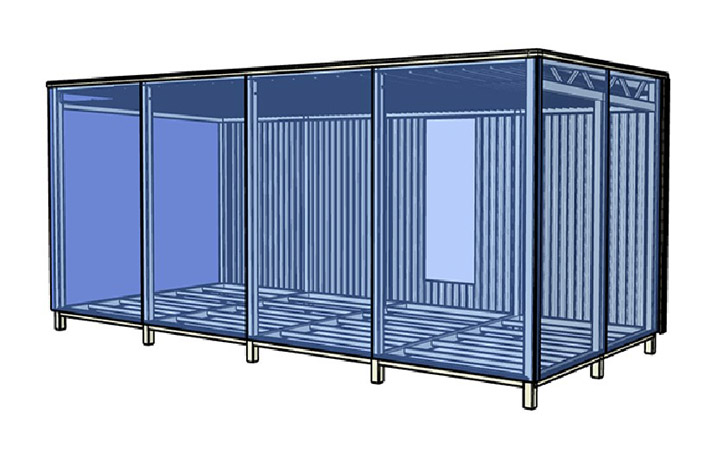

Suspended ceilings: Perforated metal is an alternative to traditional ceiling tiles that can increase a space’s visual appeal. They’re effective at covering unattractive overhead systems like AC units and are easy to install and remove. Maintenance workers will have better access to pipelines, wires. Plus, perforated metal has soundproofing characteristics.

Stair treads and risers: Using perforated sheet metal for stair treads and risers is an aesthetic and functional design choice, especially for outdoor staircases. The holes prevent slips by letting the rain and snow travel through. The material also has greater slip resistance and durability than alternatives. Perforated metal is also an excellent option for stair risers, providing distinctive design options. In industrial settings, the holes can prevent the dark and dreary feeling sometimes associated with staircases by allowing light to filter through.

Infill panels: Indoor and outdoor perforated panels can add some life to an otherwise bland space. Infill panels also provide an element of privacy, filtration, and sound control without completely sectioning off an area.

You can customize and protect your sheet metal with surface finishing. Sheet metal finishing provides even more design opportunities to add color and increase durability.

Powder coating: Powder coating adds color to your design but is much harder and more durable than regular paint.

Anodizing: This technique is also frequently used for color application. It increases the surface’s natural oxide layer’s thickness to make the metal more durable and ready for color or sealant application.

E-coating: Electro-coating, also referred to as electro-painting, uses an electric current to deposit paint or lacquer coating. It reduces corrosion and is especially useful when applying color to difficult-to-reach areas.

Silk screening: Silk screening, also known as sublimating, is an ideal solution for printmaking on perforated metal, as it requires no pressure nor a planar surface to apply.

Polishing: Polishing removes abrasions from the surface of metal, leaving it with a smooth, clean, bright finish.

Deburring: Grinding, drilling, or punching can leave burrs, or unwanted excess materials, on the metal’s surface. Deburring removes these imperfections to give the perforated metal a cleaner finish.

Degreasing: As its name suggests, degreasing refers to removing dirt, oil, and grease before finishing.

Plating: Plating refers to putting a thin metal layer on the surface, improving corrosion resistance, paint adhesion, and durability. Plus, it enhances sheet metal’s aesthetic appeal. You can better shield radiation, harden objects, and reduce friction with electro-plating.

Passivating: Decreasing the metal’s chemical reactivity, passivating makes surfaces more resistant to extreme conditions and protects against corrosion.

Chromating: Chromating can prepare the surface for paint, increase resistance to corrosion, and ensure the surface is electrically conductive.

- Address

No.3 Beishang New City, GongShu District, Hangzhou China

-

Phone

+86-18072735884

-

Landline

+86-571-88688170

English

English